50 years of Dugar + Schuster

1974 – 2024

The year is 1978

After 2 weeks of negotiations, the peace treaty between Egypt and Israel is signed in Camp David; the Arab world is critical of this.

1978 is the year of the 3 popes, Karol Wojtyla is the first Pole to be elected the new pope and retains the chair in the Vatican for several decades.

The VW Golf comes onto the market and the Parker company invents the ballpoint pen with a push mechanism.

In Bavaria, Franz-Josef Strauss was elected Prime Minister with an absolute majority; he, too, will retain this office for a long time and shape the political landscape in Germany.

Germany becomes handball world champion and 1. FC Cologne becomes German football champion.

After more than 10 years of abstinence, Mike Hailwood wins the legendary motorcycle race on the Isle of Man with DUCATI. https://www.youtube.com/watch?v=U8t4ILQKAZA&t=4s

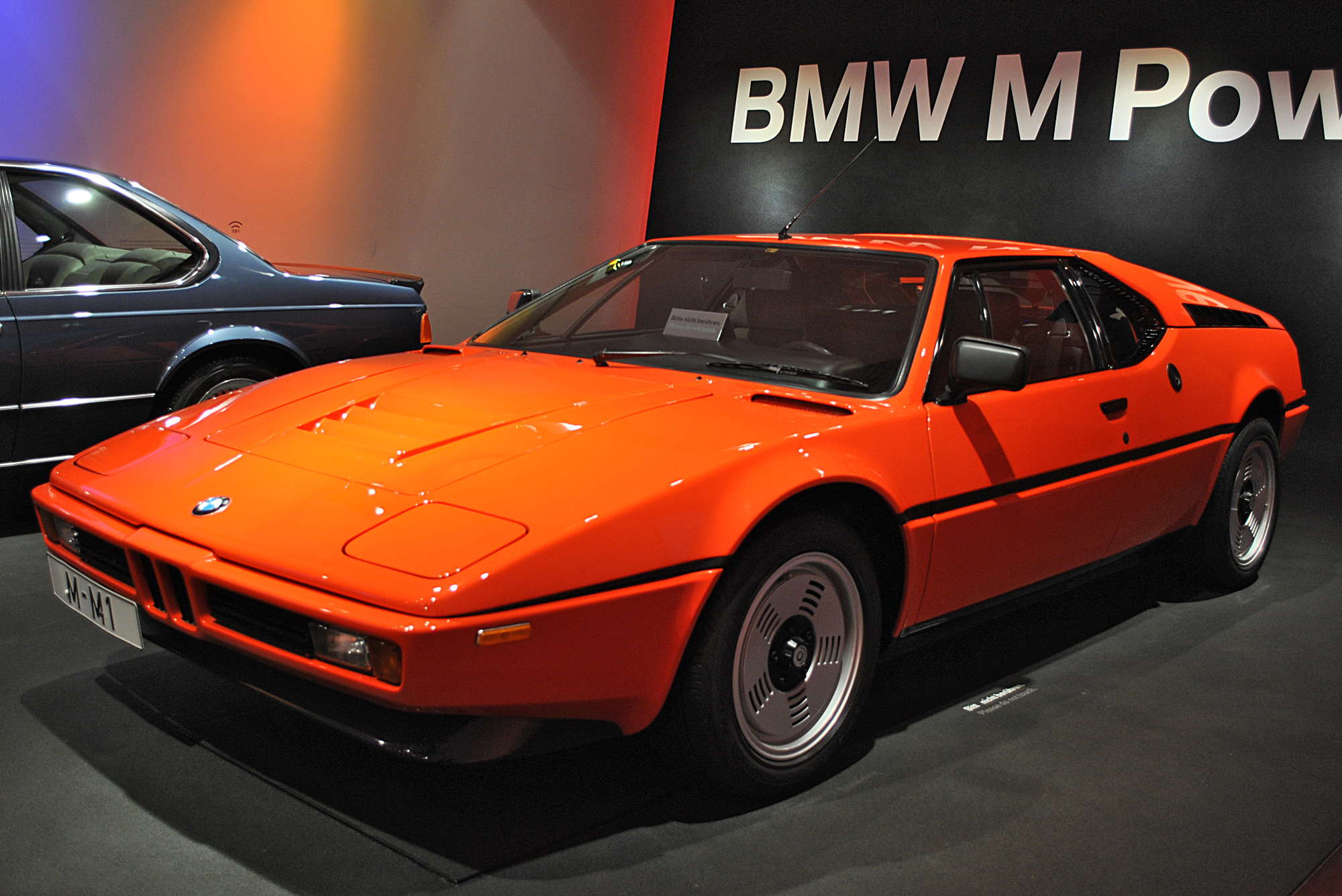

BMW starts small series production of the M1 sports car.

Dugar + Schuster sells the first heavy-duty lathes from TACCHI from Italy – a tradition that continues today.

The aluminum wheel or commonly called the “aluminum rim” is not only used for sports purposes but also for sporty drivers – manufactured by established companies such as Otto Fuchs Metallwerke, Kolbenschmidt or Mannesmann Kronprinz.

But aluminum wheels were also brought onto the market by racing-enthusiastic entrepreneurs with the companies ATS, BBS, Borbet, Campagnolo, Cromodora, OZ, Rial, Ronal and Speedline.

Image: BMW M1 with it’s original Campagnolo wheels https://de.wikipedia.org/wiki/BMW_M1

A new market

Dugar + Schuster is entering this growth market as a pioneer by selling the copy-controlled vertical lathes from TVA from Italy, which are specially designed for the aluminum wheel product. (The photo, however, shows a more modern CNC controlled machine with a pallet changing system from the same manufacturer)

With these machines the success story of Dugar + Schuster began in the hotly contested market for aluminum rim production.

The series production of aluminum wheels with a high machining volume has always had to be carried out as effectively as possible, which is why TVA lathes with up to 3 carbide tools working at the same time came in handy.

The vertical spindle also made inserting and removing the wheels by hand much more ergonomic than the competition with a horizontal spindle.