Aluminium - Wheel machining

High-performance vertical turning lathes with 2 and 4 axes for all wheel sizes, including truck wheels. Special designs for high-precision machining.

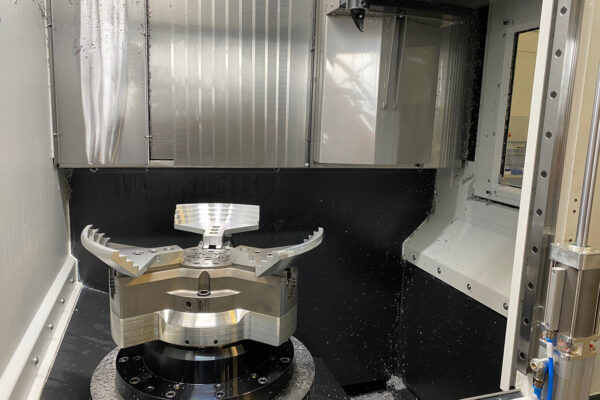

Two-axis CNC vertical lathe RDM-G

As a result, these are equivalent to polished surfaces, with significantly lower costs and significantly shorter cycle times. As shown, also available as a double machine with a CNC. The machine has a machine bed in a hybrid design with optimal vibration damping in a space-saving design.

This means it also fits into small work spaces.

The RDM-G can also be equipped with linear axle drives, making it suitable for a wide range of applications. We received an order from a well-known company that produces alloy wheels with the highest surface quality. The RDM-G meets these requirements.

Machining OP 1 of a light alloy wheel.